What is Frequency Inverter?

It is an electronic device used in industrial automation, allowing total control in the drive and conditioning of 3-phase motors. Allowing discrete sensor drives, button-tools, local keyboard and network protocols.

Main functions

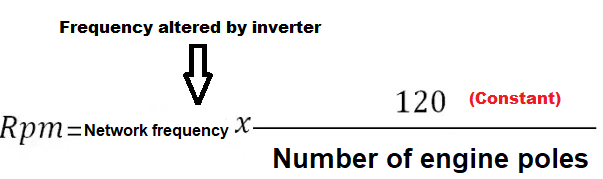

Rpm= Number of 3-phase motor laps (turning speed).

The main function is the motor speed control.

As seen above in the mathematical formula, the only variable data is the frequency of the network. The inverter provides a variable and programmed frequency in its output contacts, easily enabling the 3-phase motor to change speed.

Pre-Configured Frequency

In industrial processes several operations are carried out dynamically, analog control resources and also preconfigured frequencies is widely used in Industrial Automation.

The speed reference can come from an analog level sensor (0 to 10v/4 to 20mA) or by PLC outputs and digital sensors that activate frequency inverter inputs according to the generic table:

| [Pre-Configured Frequency 0] | 5,0 Hz |

| [Pre-Configured Frequency 1] | 10,0 Hz |

| [Pre-Configured Frequency 2] | 15,0 Hz |

| [Pre-Configured Frequency 3] | 20,0 Hz |

| [Pre-Configured Frequency 4] | 25,0 Hz |

| [Pre-Configured Frequency 5] | 30,0 Hz |

| [Pre-Configured Frequency 6] | 35,0 Hz |

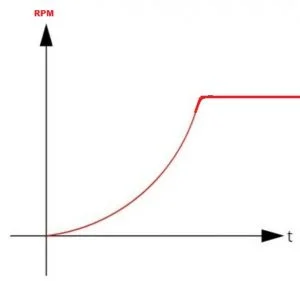

Acceleration/Deceleration Ramp

Allows a smooth start/off of the engine, thus avoiding electric current spikes and mechanical damage to the reducer or load.

Example

A car aims to reach the speed of 100km/h. Being fully standing goes from 0 to 100 km/h in 20s. (Acceleration ramp of 20s)

3-Phase Motor

The minimum frequency programmed at 50 Hz and the acceleration ramp 5s, then:

The engine being fully still goes from 0 to 50 Hz in 5s. (Engine acceleration ramp).

Main Features

- Analog control.

- Protection against electrical surges.

- Limitation of current peaks.

- Limitation of voltage dropouts.

- Compact

Applications

- Mats.

- Endless threads.

- Bombs.

- Control.

Main errors

- Short for ground, motor cable is in short or rated current parameter too low.

- Overload, rated current above the limit “overloading the engine”.

- Low voltage, lack of phase in the network or defective.

- Communication error, happens when the inverter works on a network and the IP address is not found, and may be network card, faulty cable, or incorrect IP address.

Parameters

Group 1: Engine data

The data of the three-phase motor plate is inserted, this data provides important information thus ensuring perfect operation and electrical protection.

Group 2: Conditioning

In this group is due to the type of start, control method, range of operation (Freq Max/Freq Min) and also the time of the acceleration/deceleration ramp.

Group 3: Advanced

The number of advanced parameters vary greatly with the inverter model, in different applications are required activated analog inputs, digital inputs, network protocols, PID control, torque and feedback outputs.

The possibilities are huge we recommend that they perform the programming used in the manufacturer’s manual.

Practical Summary

Based on our previous posts (Star/Triangle Match, Frequency Inverter and Soft Starter) and with the concepts of each device, we created a table.

| Practical Examples | Speed Control | Torque | Future Changes | Decisão do projeto |

| Ventilator | No | No | No | Star Match / Triangle |

| Process mat | Yes | No | No | Frequency Inverter (simple) |

| Mixer | No | Yes | No | Soft Starter |

| Endless thread, Heavy Process. | Yes | Yes | No | Frequency Inverter (Advanced) |

| Mixer | No | Yes | Yes | Frequency Inverter (Advanced) |

We at Way Automation reinforced the good installation practices thinking about future maintenance, ensuring quality, meeting the customer’s need, and the most important personal and equipment safety.

Conclusion

The basic characteristics and parameters do not differ in the various brands and models of the frequency inverter. As seen in this post the frequency inverter is a great resource in industrial automation, having parameters of conditioning, process control and remote communication between devices.

Legal Notice

All information obtained on this website and related social media pages is for INFORMATIONAL purposes only. The Way Automation is NOT responsible for any damage or loss caused by the execution of actions related or not to the content described here. Always look for a qualified professional, follow the rules and use protective equipment for any work that involves electricity.